Beer-Tasting Never Saved the Planet

From Apprentice to Malster Master

AB InBev has amazing brands. I finished school and set my sights on getting involved with the Beck's brewery in Bremen, Germany. It has a worldwide reputation, so I knew it was the right place to make an impact.

When I joined AB InBev as an Apprentice for Brewing and Malster, I was impressed with the sheer scale of training they offered. They sent me on a three-year training course where I learned everything about producing malt and the complete brewing process – from raw materials to fermentation and bottling. That training gave me all the skills I needed to progress my career within the brewery to where I am today.

Training the taste buds for success

Here's the best bit of my job: I test our beers for taste, color and carbs – it's not something everybody can say they get to do at work! It's a big responsibility that takes precision and detail. I test the beer at every stage from fermentation to storage, checking the taste and sensory profile to make sure it's exactly as it should be. We're trusted to make sure the beer is perfect for our customers.

Everyone here knows what great beer should taste like: AB InBev provides taste training for all new employees. 34 years of experience has trained my taste buds well – I've tasted millions of beers by now. Each morning at 8:30am, I taste 10-15 bottles of beer along with five other people. If we say it's good, it's ready to go.

Challenge accepted: saving the planet

I've always been in pursuit of efficiency: it's a key goal of AB InBev, and throughout my career here I've been involved in reducing cost, waste and pollution for the brewery. It's a personal goal for me, but also a company-wide one. When a great, innovative idea helps us work towards our sustainability agenda, AB InBev encourages and rewards it.

Thinking sustainably is a vital part of what we do – and I'm proud to say I've developed some innovative ideas along the way to help us hit our sustainability goals. In my early years here, I developed a technique to save water in the brewing process – a big part of our sustainability agenda. Since then, I've led projects on other ways we can help save the planet as we brew the world's best beers – like reducing our carbon waste by collecting excess C02 produced during fermentation and re-using it in other parts of the brewing process. Beer tasting and brewing might not sound like it can save the planet, but we're proving every day that it does.

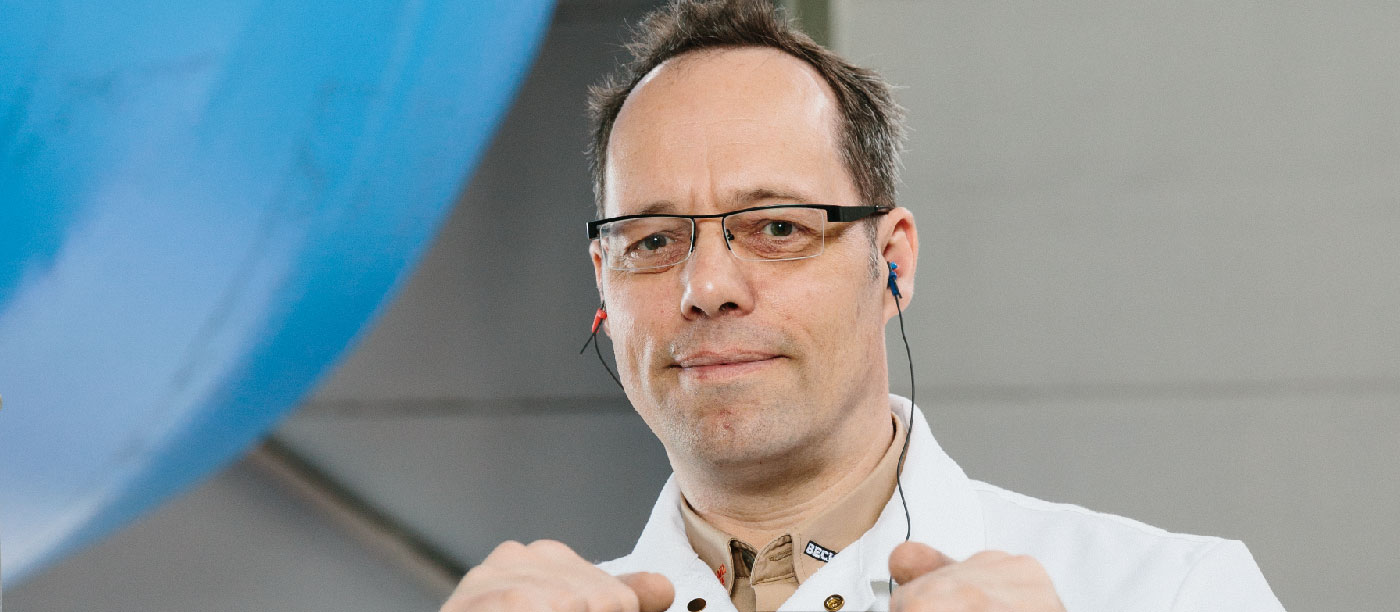

Great beer is in Fred's nature. Since starting as an apprentice with AB InBev, he's been taste testing the world's top beers with us for over thirty years. Now, as a Brewing Operator, he's developed innovative ideas along with delicious beers – ones that are helping us save the planet.